Making Miniatures Fly at Gulliver’s Gate

We talk to Adrian Davies, head of model-making, about the 2,200 square foot airport they’re building

In order to get a New York City resident into the heart of Times Square, the attraction must be one of pure magnificence. That’s exactly what we found with Gulliver’s Gate, a massive world of miniatures unlike any other. This isn’t a novelty experience; rather, it’s a technologically impressive, immersive universe that reconstructs global subjects in detail. New York City itself plays an inspiration, but one quickly ventures to scenes from Europe, Latin America, the Middle East and Asia. Gulliver’s Gate occupies an entire city block. Within, each model captivates with scope, scale and movement. Employees from eight countries across four continents constructed all of the elements and the assembled result is roughly the size of a football field.

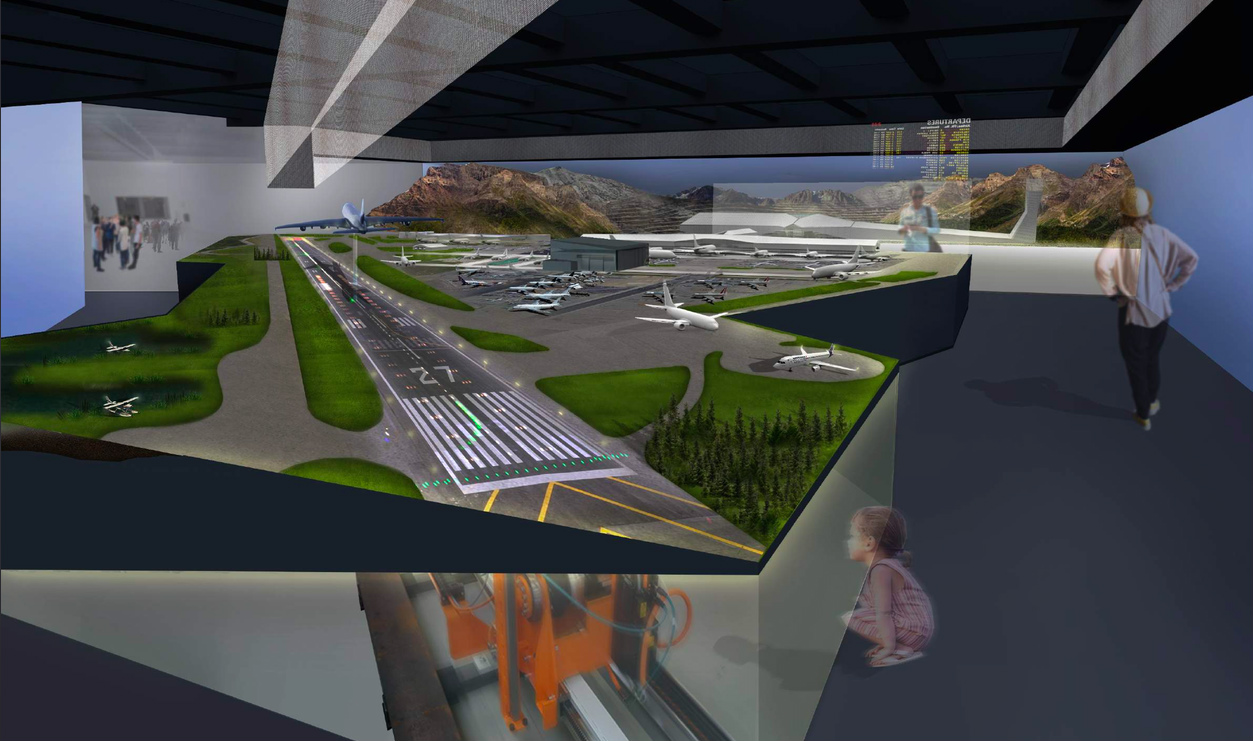

While professional model-makers were recruited from around the world (and each used their own methodology), an in-house team of professionals has been developing several components, as well. The biggest one—at 2,200 square feet—is a 1:87 ratio model airport replete with planes that take off and ground crews scooting about. Still under construction, the airport’s runway is 50 feet long, has three motors and planes rise up three feet into the air (on a glass rod) before disappearing into clouds. From wireless charging components to satellite technology embedded in the ceiling, connected to emitters in each vehicle, an array of advanced technology has been deployed to animate the experience. We spoke with Adrian Davies, Head of Model-Making at Gulliver’s Gate, to get a deeper sense of the work.

Davis actually began making models as a child, an interest that extended to building everything from go-carts to gadgets. Realizing the passion could become a profession, he took a degree in model-making from the UK’s University of Sunderland. For 15 years, he had been making architectural models in the NYC until joining Gulliver’s Gate in July 2016. At this time, the space had been selected and much of the design and conceptualizing was underway—including the schematic design for the airport.

“Airports are exciting to look at,” Davis explains to CH. “They’re really fascinating places. Infuriating as well.” The airport has posed many unique challenges. “Getting everything to line up,” Davis continues. “It requires phenomenal accuracy to get the planes to fly.” There are 50 aircraft planned, as well as ground service vehicles and employees. Completion is expected in the fall, but in the interim, guests to Gulliver’s Gate can actually watch pieces being made on site. Workshops are all visible to those in attendance. “It’s really good for a kid or an old timer,” Davis continues, “It’s so much of a two-way dialogue. It’s like chatting over a garden fence and a really big part of the experience.” While on site, we found it quite fascinating, but also inspirational.

Davis says that 3D printing has been the biggest innovation in model-making in 20 years, following up laser-cutting. Much like with the adidas futurecraft 4D, the team at Gulliver’s Gate employ a Carbon printer. “That thing has been an absolute godsend. It’s like the 15th team member. It’s so useful because you can turn around parts so quickly,” he says. As for quick turn-around, one of the most charming features of Gulliver’s Gate happens to be that all visitors can 3D print themselves and be added to the model. Davis hasn’t yet done so for himself, but he knows exactly where he’ll place himself: “Next to Totoro at the bus station.”

Sneak peek tickets are on sale now for $25. Gulliver’s Gate opens officially at 216 West 44th St on 8 May.

Images courtesy of Gulliver’s Gate