Shinola Watch Dial Factory Visit

Brand president Jacques Panis walks us through the new state-of-the-art facility

The resurgence in stateside manufacturing is largely thanks to more educated and passionate consumers. Where a product’s merit was once simply its final form, there is an ever-growing demand for products with a story that embody considered design and stand up to the highest degree of quality. One of the most vocal and committed to American manufacturing in the consumer space is Detroit-based Shinola, a brand we’ve covered since its launch in 2012. In addition to bicycles, leather goods and stationery, the brand’s watches have gained the attention of horology fans the world over. Their latest in the push for American-made components in their products is a watch dial factory, placed right in the Motor City flagship store.

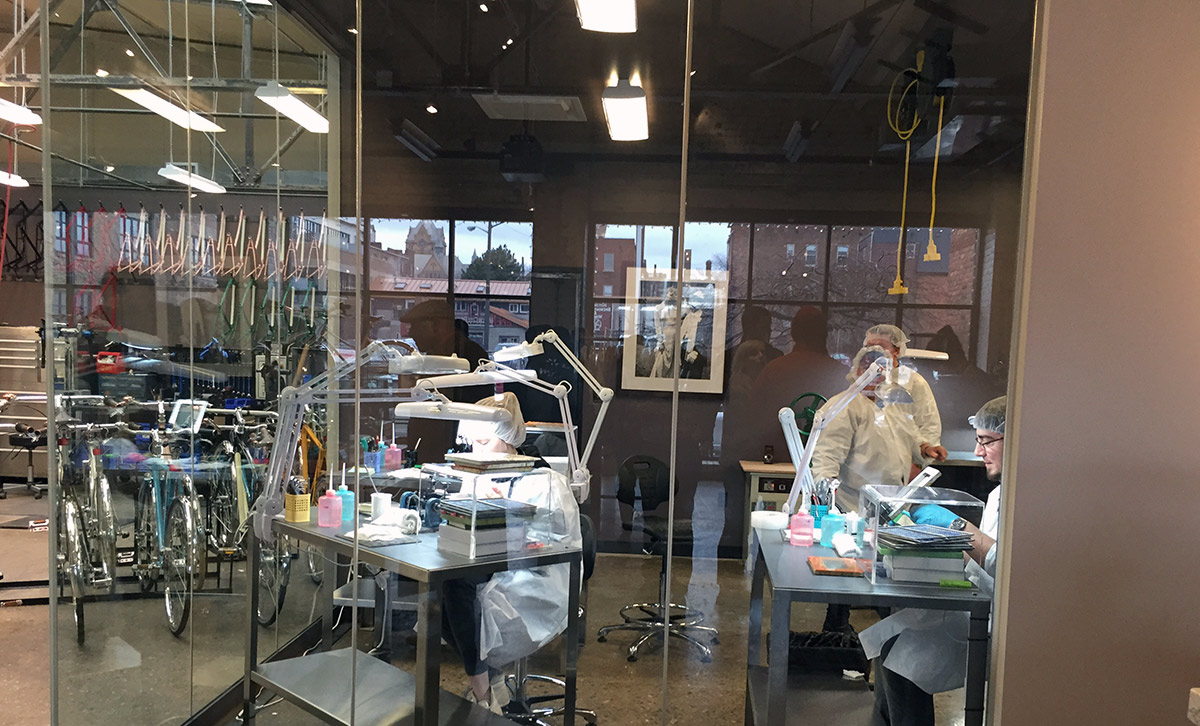

“It’s one step closer to us making watches of 100% American-made components, at scale, here in the US,” says Shinola’s president, Jacques Panis. Few watchmakers produce their own dials and straps, and even fewer American watchmakers take on this technical—if not high-tech—manufacturing challenge. Over the next six to nine months, the factory will expand from four to 10 employees, with the goal of a full cut, colored and ready-to-place dial production line.

Placing the dial factory in full view of customers is an important component in telling the Shinola story. “When a consumer buys that dial, they’ll know that this dial in this watch was made right here in Detroit—they saw them being made,” Panis explains as a screen is pulled for a Runwell dial. “That’s the real important piece of this puzzle—the consumer being able to see that this is being made [here].”

Manufacturing is as much a part of Detroit’s soul as Motown, and its skilled workers come from a lineage of making lasting products, “These are Detroiters,” says Panis. “John, the leader in the factory, comes with [a lot] of manufacturing and manufacturing process [experience], so he’s a real professional when it comes to setting up these types of lines.”

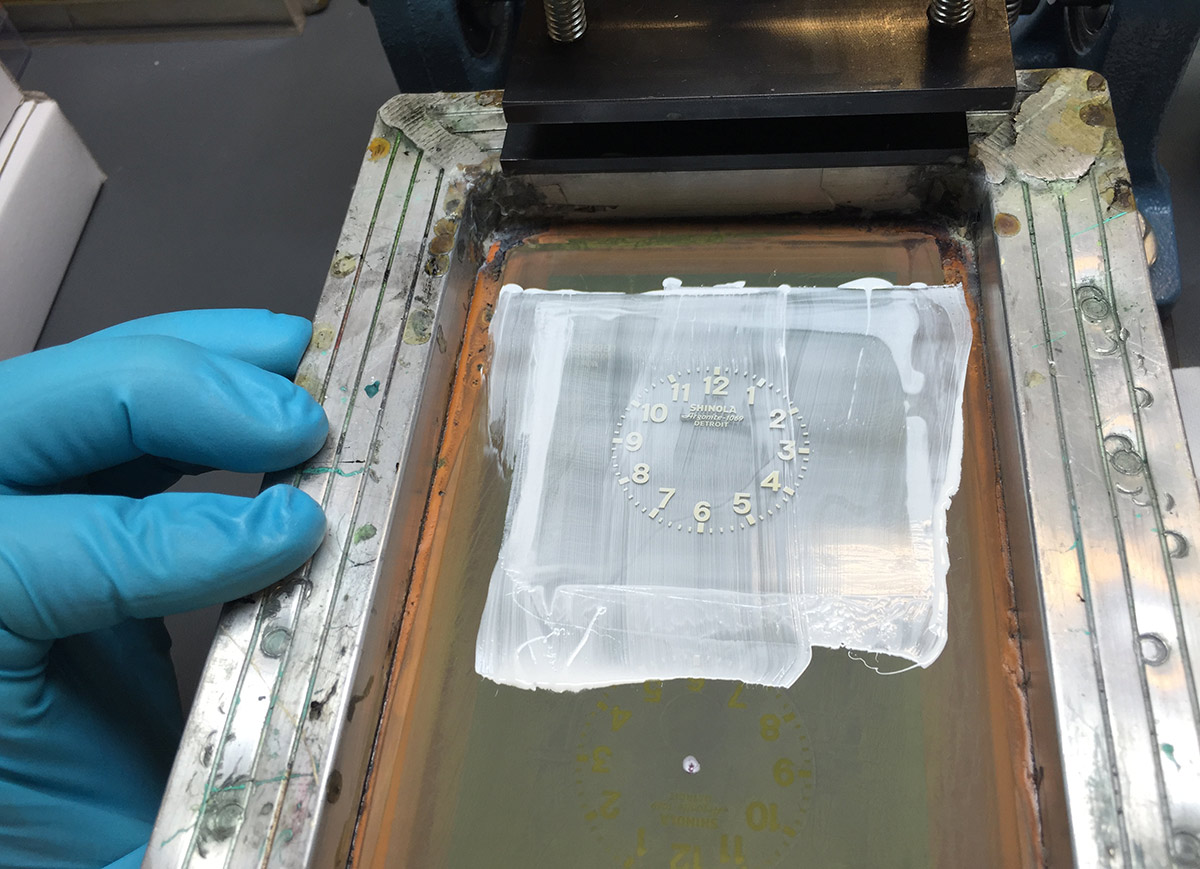

In this sterile room—visible through its glass walls to everyone in the store—precision is the name of the game and every surface is perfectly level. A speck of dust in a dial can render it unusable. A dial is made of up to eight separate layers with curing time in between. The screen artist makes dials a batch at a time; placing the dial, making a pass, and setting it to cure for several minutes before replacing each dial in the batch into the set up and screening the next layer. Each round creates more room for error. We asked Panis if having an on-site dial factory could give Shinola the opportunity for customers to customize, or give Cool Hunting the opportunity to create a special edition. While we didn’t get a firm “yes,” he suggested that at some point in the future it may be a possibility.

“For me, it’s exciting because of the evolution from the brand perspective,” Panis says. “We’ve always said we’re going to do more and more here in the US and we’re sticking to the promise. We’re being transparent about it, we’re being open about it—no smoke and mirrors here.” With its facility in the open, Shinola is wearing its commitment to Detroit and the American workforce on its sleeve. “There’s no reason we, as Americans, can’t do this here. We can do this, and we can do it well,” Panis adds with confidence.

Images by Evan Orensten